We are a professional electric coolant pump BMW supplier. Welcome to visit and purchase our BMW electric water pump.

電動クーラントポンプは、エンジン制御モジュール(ECM)によって制御されます。エンジン管理システム(DME)は、エンジン負荷、温度、動作範囲、およびその他の要因を使用して、クーラントポンプの動作と速度を決定します。ポンプには自己診断機能もあります。次の条件の障害コードはECMに保存され、診断に使用できます。

- ポンプ羽根車の速度偏差

- ポンプシャフトの剛性または異物による閉塞

- 誤った水/クーラント混合物

- 冷却システムを換気する

N52またはN54 6気筒エンジンを搭載したBMW E60モデルでは、クーラントポンプは、エンジンブロックの右前部にボルトで固定された外付け電動ポンプです。エンジンが駆動しているかどうかに関係なく、またエンジンの回転数に関係なくポンプが動作できるため、電動ポンプを使用すると(エンジンベルト駆動の種類とは対照的に)エンジンの冷却効率と寿命が向上します。たとえば、コールドスタートの状況では低流量を維持してエンジンを急速に暖めるのに役立ちますが、高流量を使用すると、エンジンが停止したときなどの急速な冷却に使用できます。

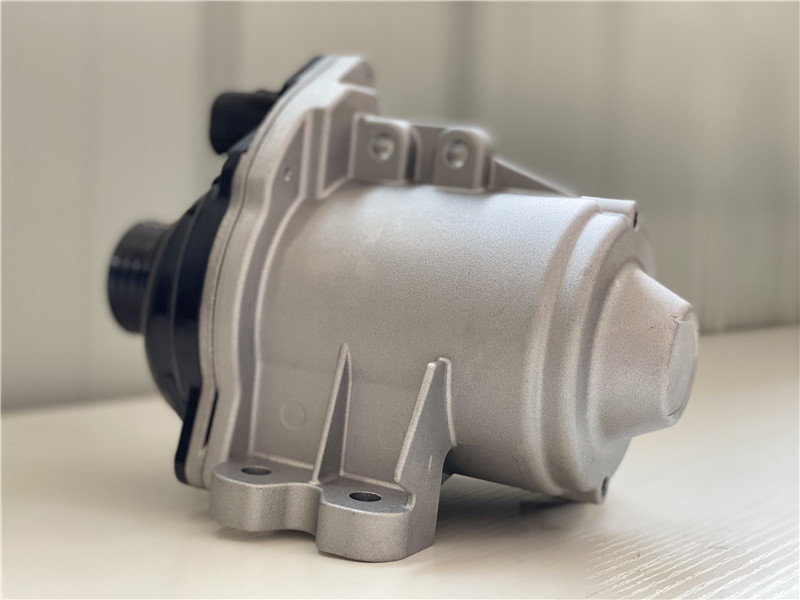

11517588885 11517632426 BMW電動ウォーターポンプ

原産地:中国、長州

銘柄:BESTJOYI

保証期間:1年

OE NO:11517588885

車モデル:BMW

パッキング:ニュートラルパッケージ

配達時間:7-15日

品質:高品質

サービス:24時間のカスタマーサービス

MOQ:10ピース

JIAYANG Electronic Coolant Pump BMW

JIAYANG is the global leader in automotive cooling system motion solutions. The increasing demand for fuel economy improvement and emissions reduction, together with growing HPEV/EV applications, have created the need for more efficient and smarter cooling systems. For powertrain & drivetrain cooling, JIAYANG offers electric coolant pumps with best in class efficiency and reliability for main engine cooling or auxiliary coolant circuits (e.g. battery cooling, cabin heating, etc.).

The electronic coolant pumps serve a function of supplying coolant to other components in thermal management systems. By precisely cooling the target when only necessary, electronic coolant pumps save power consumption and reduce emissions.

JIAYANG’s electronic water pumps are used for the start/stop technology, turbo cooling, engine cooling in the conventional full vehicles, as well cooling batteries, DC/DC converters and power electronics in hybrid and electric vehicles.

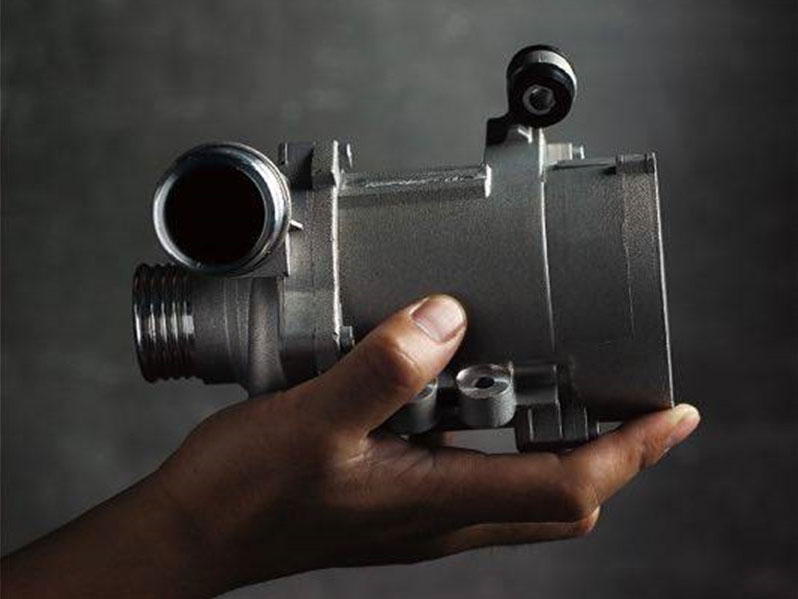

11517586925 BMW電動ウォーターポンプ販売

原産地:中国、長州

銘柄:BESTJOYI

保証:12か月

OE NO:11517586925 11517586924 11517521584

車モデル:128i 328i 528i X3 X5 Z4

車の備品:bmw

製品名:電動ウォーターポンプ

用途:128i 328i 528i X3 X5 Z4

素材:プラスチック、スチール

品質:100%テスト済み、高性能

MOQ:10個

配達時間:7-15日

Advantages

- The cooling system forms a closed circuit. Its task is to ensure thermal equilibrium in the engine. The cooling liquid absorbs the heat from the engine block and cylinder head and releases it into the ambient air through the radiator.

- The engine only has ideal operating conditions, with high efficiency, complete combustion and reduced emissions, at optimum temperatures.

- Standard mechanical water pumps are driven directly by the engine. When the engine is running, they pump coolant continuously – even if cooling is not required.

- The electrical coolant pump with integrated electronic control system is, however, continuously connected if cooling is required. For cold starts, the electrical coolant pump does not pump to begin with. This enables the engine to reach its operating temperature more quickly.

- The electric coolant pump is also able to generate sufficient cooling capacity when idling or after the engine is switched off because it is not linked to the engine speed. This on-demand cooling of the engine reduces power requirements whilst also cutting down on frictional loss, fuel consumption and pollutants.

- Electric coolant pumps make a significant contribution to emission control in modern engines.

- Electric coolant pumps are affixed outside the engine. The electric motor of the pump is cooled by coolant.

- Electrically driven coolant pumps work with engine-independent and demand-based operation.

- On-demand cooling helps to reduce fuel consumption during the cold start phase, and lower exhaust emissions.

- The speed and delivery rate of the pump are independent of the engine speed, and are regulated by the control unit such that the optimum operating point is always attained.

- Continuous control through actuation via pulse width modulation (“pulse duty factor”)

- Delivery rate wholly independent of the engine speed of the vehicle

Diagnostic capability